In the 1940s, the Hungarian American mathematician and engineer John von Neumann was working on the theory for a “universal constructor.” This idea was for a machine that could produce other machines—including machines that, like itself, were machine producing. These machines would be designed to pass information on from one generation to the next so that they could evolve in complexity, as in the evolution of biological organisms. What this idea holds at its core is the possibility of fully automated production—machines making the machines to make anything else people might need, creating productive abundance on their own.

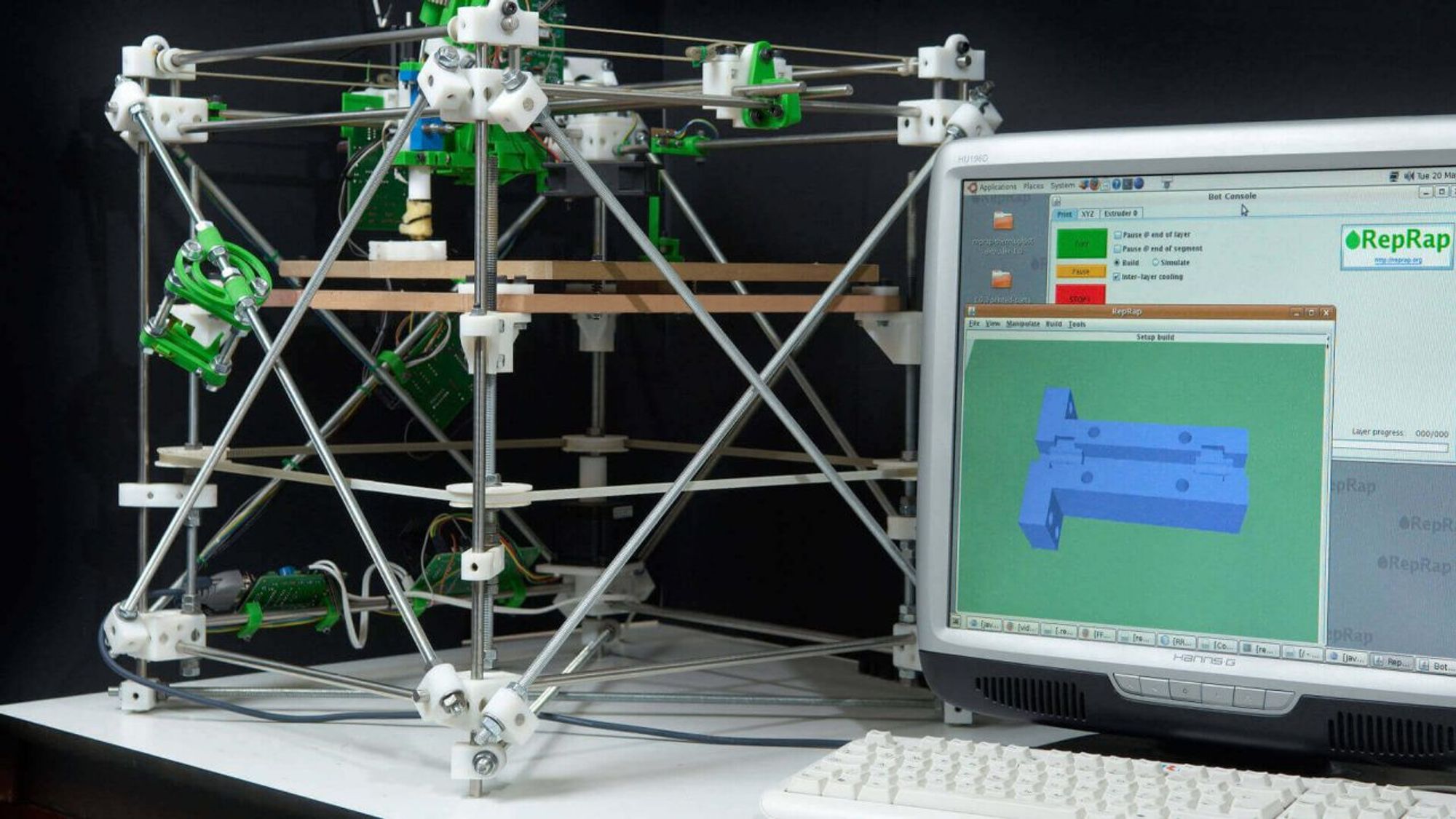

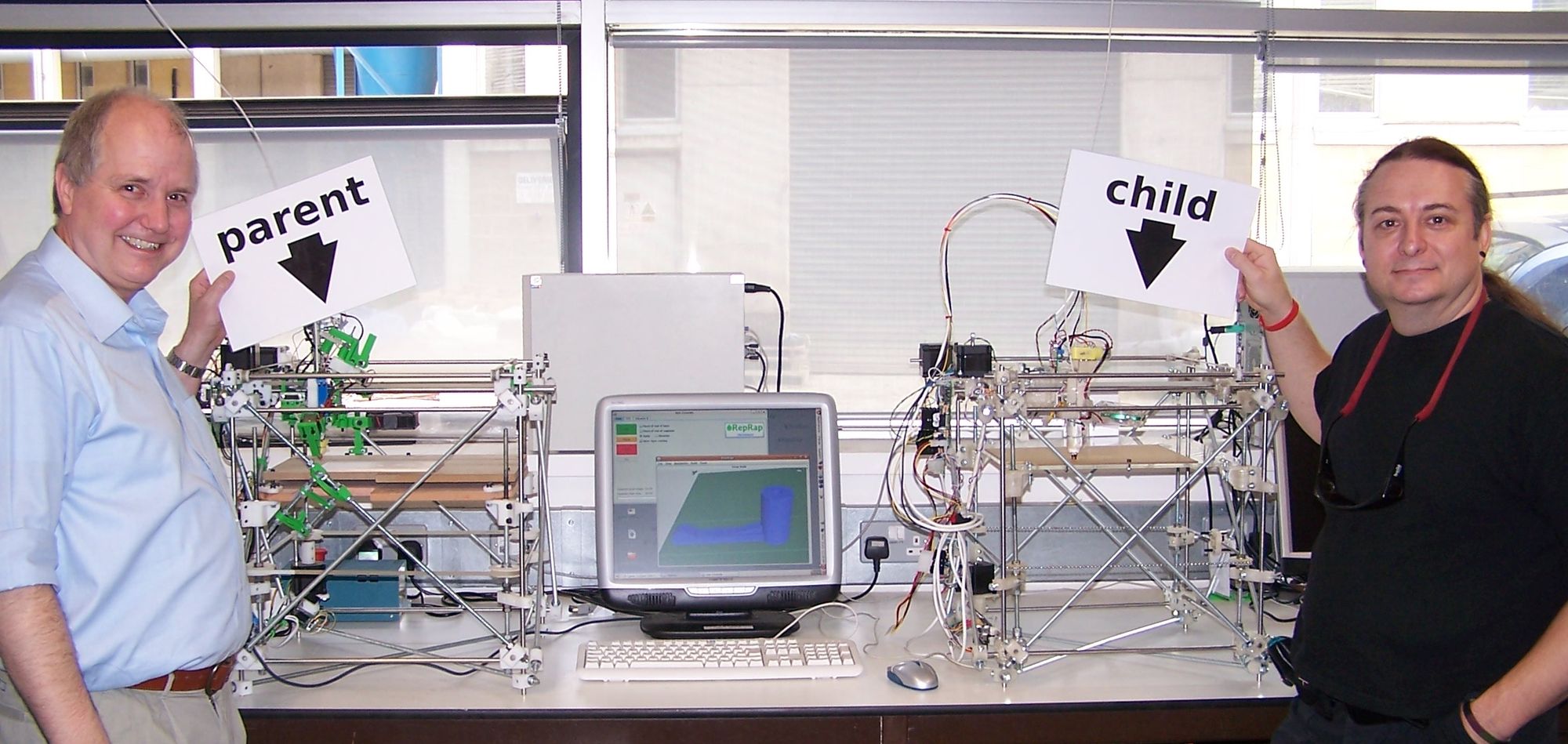

One of the direct inheritors of this theory is the British engineer and mathematician Adrian Bowyer. In 2005, Bowyer set out on an ambitious project that now includes hundreds of collaborators from around the world. The RepRap project intends to produce a pure self-replicating device. Its name short for “replicating rapid prototype,” RepRap is an attempt to prove that “rapid prototyping and direct writing technologies are sufficiently versatile to allow them to be used to make a von Neumann universal constructor.”[i] The practical implications for this would be that people all over the globe could set up their own self-sustaining nanomanufacturing systems to produce many of the objects used in everyday life. By 2008, RepRap 1.0 (nicknamed “Darwin”) made more than half of the parts for a new version of itself. The project continues in an effort to achieve the broader vision of a truly distributed, democratic, peer-to-peer model of material production.

RepRap is an open-source hardware project: the designs are made publicly available so that anyone can make their own device, including modifying and distributing new hardware based on that design. The open-source hardware concept encourages peer-to-peer collaboration so that the development of technology can take place in socially coordinated rather than corporate-controlled ways, with many people sharing knowledge in the process of exchange. “The picture that is beginning to emerge, then, is that the benisons [or blessings] of digital production can be enjoyed most widely and most equitably when fabrication engines of a few different kinds are deployed in neighborhood-scale shared workshops.”[ii] Many of the challenges for scaling up this vision are, of course, posed by the commercialization of 3D printing. For many of the early enthusiasts, the vision of an autoindustrial, postscarcity world was their motivation, not narrow commercial success. This early foray into digital and autoindustrial production has generated a variety of interrelated projects that aim to create a robust ecosystem of technologies and materials necessary to realize this vision.

[i] RepRap, “Introduction,” Wikipedia, last updated May 12, 2015, https://reprap.org/wiki/Introduction.

[ii] Greenfield, Radical Technologies, 96.

— —

See also: https://www.reprap.org/wiki/RepRap

👉 Home